|

|

|

Cost-effectiveness Analysis of Soundless Cutting Mechanism Using SCA

Release Date:[2009-6-25] Press Release:

The advantages and disadvantages of SCA Soundless Cutting Mechanism as well as other methods of quarrying are listed in Figure 1. For marble and granite, the ultimate parameters used to evaluate in the cost-effectiveness analysis would be its productivity and block to slab ratio, i.e., the volume of standard blocks out of 1000m3 ore body, the amount of day labour, and the proportion of standard slab out of per square meter block.

Figure 1 Comparison of Five Quarrying Methods in China

|

Methods in Contrast |

Manual |

Blasting |

Incendiary Agent |

Mechanical |

Soundless Cracking |

|

Cracking Agent |

- |

Black Gun-powder |

Metal Combustion Agent |

- |

SCA |

|

Machinery |

Hammer and

wedge |

Air Compressor,

Rock Drill |

Air Compressor,

Rock Drill |

Air Compressor Type 025,

Rig rope saw |

Air Compressor,

Rock Drill |

|

Cracking Mechanism |

Split |

Gas Expansion |

Gas Expansion |

Machinery Cutting |

Expansion of Solids |

|

Hazard |

Vibration,

accident-prone |

Explosive,Vibration of Shockwave,Harm Ore Body |

Explosive,Light Vibration of Shockwave,Harm Ore Body |

N/A |

N/A |

|

Construction Difficulty |

Easy |

Less Complicated,

Dangerous |

Less Complicated,

Dangerous |

Complicated,

No Danger |

Easy,

No Danger |

|

Initial Capital

Outlay |

Smallest |

Small |

Large |

Largest |

Small |

|

Productivity

Per Worker |

Lowest |

Low |

High |

Highest |

High |

|

Ore to Block

Ratio(%) |

App. 40% |

App. 20% |

App. 30% |

>50% |

>50% |

|

Block to Slab

Ratio(m2/m3) |

20~25 |

11~21 |

15~25 |

30~35 |

25~30 |

|

Specification

of Block(m3) |

1~2 |

1~2 |

2~3 |

3~10 |

3~10 |

|

Overall Performance |

Poor |

Poor |

Normal |

Excellent |

Good |

It can be seen from the above figure that, the manual method costs the least, but requires high level of labour intensity, with the lowest productivity, also it cannot quarry out big blocks; Blasting method has a high efficiency, but the ore to block ratio is low, as the shockwave of explosion would hurt the block, low the block to slab ratio, thus not economics for both mining enterprises and stone processing enterprises. Application of wire saw and diamond saw method is the most technologically advanced, has the highest ore to block ratio and block to slab ratio, as well as production efficiency. However, it requires huge initial capital outlay, technical personnel, therefore it is suitable for large-scale mining enterprises, for small and medium-sized mining is very difficult to invest,especially stone township mining enterprises. The SCA cracking method requires low investment, simple construction, also enjoys high ore to block ratio and block to slab ratio.

The overall cost of SCA quarry method varies for different mining enterprises, mainly it includes mechanical drilling cost, SCA cost and labor cost.

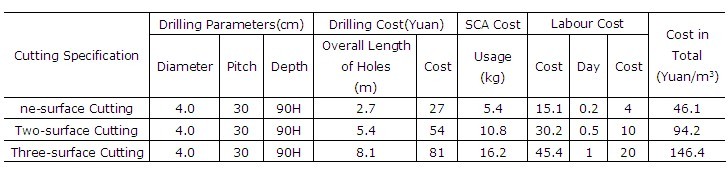

Under the current market price, Φ40mm drilling holes would cost about 10Yuan/m(oil, electricity). Manufacturer’s price for SCA is about 2.5Yuan/kg, while sales price is about 2.8/kg; workers cost 20Yuan/person • day. Take cutting 1 cubic meters block for example, the estimated quarry cost is shown in Figure 2.

Figure 2 Estimated Cost for Cutting One Cubic Meter of Block

According to the colour of marble and granite varieties, specifications of size and quality(block to slab ratio), the current market price is about 500~1500Yuan/m3. Though SCA method costs more than manual and blasting method, it enjoys high ore to block ratio without hurting the block, and high quality. One more cubic of block is a money of earning. Therefore, SCA cutting method has the highest overall cost-effective efficiency as well as social benefits.

|

|